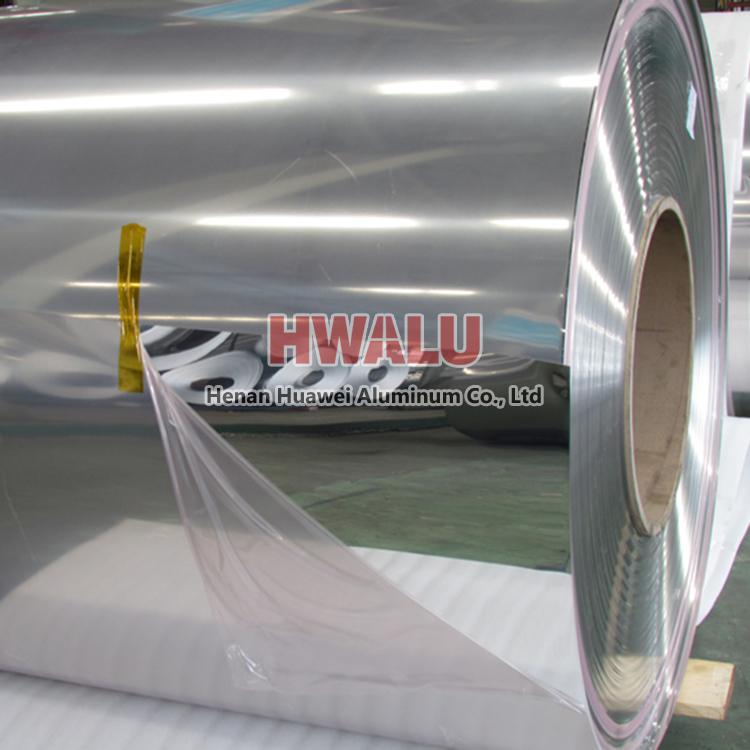

what is a mirror finish aluminum coil?

Mirror aluminum coil is calendered aluminium coil, polished aluminium coil into mirror effect. Using high purity aluminum billet, combined with high-precision equipment, can make mirror aluminum surfaces smooth as a mirror, thin lines, high reflectivity, and can meet all kinds of mirror aluminum requirements. We have the technical capability to process mirror aluminum into all hard, semi-hard, and soft states. It can be cut and leveled according to the width and length required by users.

Advantages:

- Stable price and cost saving

- High reflectivity and energy saving

- Light in quality and easy to form

- The surface is hard and hard to scratch

- Direct processing without pretreatment

application and Package:

| Application:

Lighting, interior decoration, household appliances, electronic products, automotive interior and exterior decoration, signs, billboards, bags, cosmetics packaging and other fields. |

|

|

Package:

⑴ Generally divided into vertical and horizontal packaging. Horizontal packing is more common. ⑵ When a horizontal aluminum coil is loaded into cabinets, it is generally laid in a single layer. (If stacking is required, the customer's consent should be sought first, because the aluminum coil on the upper layer will be removed from the wooden bracket) ⑶ Aluminum belt for vertical packaging. Vertical packing is more expensive than horizontal packing. |

Specifications of mirror aluminum coil

Mirror aluminum coil general specifications: 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm and 1mm thick mirror aluminum coil belongs to the general stock specifications, width of 1m or 1.25m. We can cut all kinds of aluminum strips according to the width required by users, and also can provide flat aluminum plates of fixed length.

We can provide h18 hard mirror aluminum coil, H24 curved semi-hard mirror aluminum plate, H0 lamp shade deep mirror aluminum coil.

Specular aluminum coils are available in widths ranging from 200mm to 2000mm. Specifications are available according to user's inner and outer diameters. Provide domestic mirror aluminum coil (hot rolled and cast rolled mirror aluminum coil, hot rolled mirror aluminum coil subsequent oxidation) and imported mirror aluminum coil (high reflectivity, high price). Can provide mirror aluminum coil open, cutting, embossing.

Processing technology of mirror aluminum coil

Polishing mirror : common alloy 1050/1060, thickness 0.3-0.6mm, reflectivity 75%-80%, mostly used for interior decoration or lamp manufacturing.

Anodized mirror: common alloy 1085, thickness 0.2-1.0mm, reflectivity is greater than 86%, mostly used for external wall engineering, etc., good weather resistance.

The former is cheap, while the latter is expensive.